DAVENPORT, Iowa -- Enter the Northwest Mechanical fabrication shop on any given day, and you will find skilled pipefitters welding and fusing pipes for job sites around the Quad Cities. Unlike plumbers, who typically install residential and commercial water lines, pipefitters work on pipes that can carry chemicals, acids and other substances.

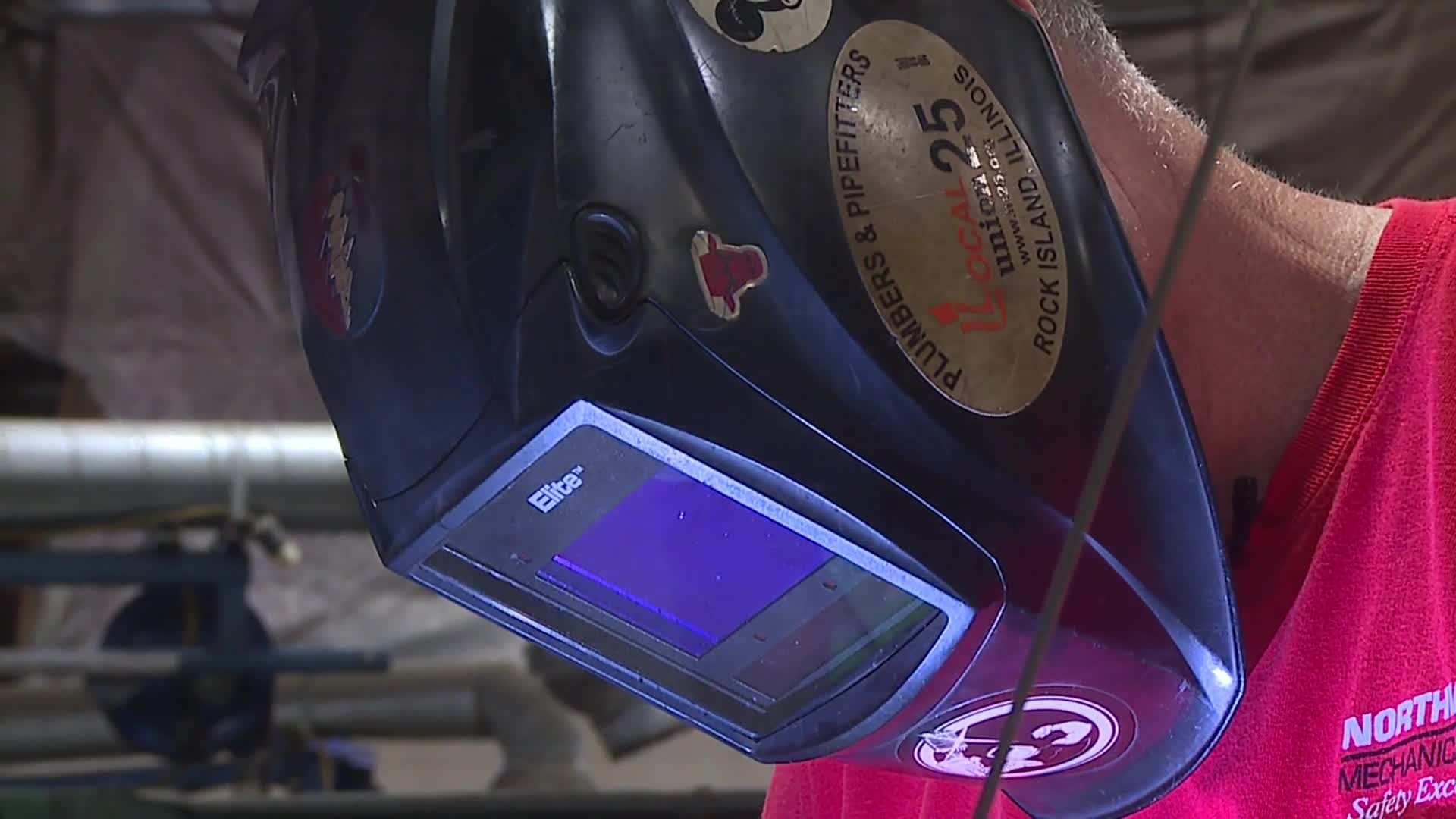

Rodney Shaw is a Local 25 journeyman pipefitter and the fab shop manager, who can often be found TIG welding. News Eight spoke with him as he was working on a pipe made of schedule 10 stainless steel, bound for a wastewater treatment plant. The process doesn't create a lot of noise, but it does produce blinding light and a lot of heat.

"It's a transfer of energy, to be able to melt the materials together," said Shaw. "Our trade is notorious for everything being hot, everything being heavy," he said.

Pipefitters work with a variety of materials and power tools. Journeyman pipefitter Chuck Cushman could be seen in another area of the shop using a chainsaw to cut through a jet black pipe made of HDPE plastic.

"There is the cut," Cushman said. "It's a little barbaric but it's the quickest and fastest way to cut this plastic pipe."

He then locked the section of pipe into place and used a facing tool to give it a smooth edge before fusing it to another section of pipe with a special tool. His measurements and the fusion joint must be precise to ensure a snug fit to match the blueprint.

"In the pipefitter realm, plus or minus an eighth of an inch is what you get," said Shaw. "If it's off an inch, it might as well be off a mile," he said.